Injection molding machine troubleshooting table——

How to check if the pump is worn or leaking and if the ram pressure is not rising

1. Fault name:

How to Check the Pump for Wear or Leaks

2. Fault phenomenon:

When the pressure rises to a certain position, it does not climb or even rises and then slowly decreases

3. Inspection items:

A. Check each directional valve for leakage

B. If necessary, the oil circuit board must also be checked

C. Check the EFBG proportional valve

Fourth, the exclusion method:

A. Manually adjust the preset pressure to above 100KG/CM2 to check whether the directional valve is leaking

B. There is a possibility of drilling at the hole where the oil circuit board should not be connected

C. If there is no problem with EFBG, lock the flow UP hole, and then slowly lock the pressure valve manually. If the pressure cannot reach above 140/CM2, it means that the pump has worn and leaked.

5. Conclusion:

Manually lock the EFBG flow orifice and the pressure slowly, and the pressure will gradually rise. If the system pressure cannot be reached, the pump is determined to be worn.

1. Fault name:

Compensation cylinder pressure does not rise

2. Fault phenomenon:

After the mold closing is confirmed, the supplementary pressure has not been able to rise

3. Inspection items:

A. Check whether the pressure and speed ammeter are working normally

B. Check the relevant lines, whether the terminals are broken or loose

C. Check whether the EFBG proportional valve is blocked

D. Check whether the supplementary pressure valve is blocked

E. Check whether the directional valve is blocked or leaking

F. Check whether the pressure shaking of the large and small pump pressure gauges is normal

G. Check whether the oil seal of the recharge cylinder is broken or worn

Fourth, the exclusion method:

A. Pressure, speed ampere pointer value and action are normal

B. Relevant lines and terminal inspections are normal

C. Detail dismantling and cleaning of EFBG proportional valve

D. The supplementary pressure valve is not blocked

E. There is no blockage or leakage in the direction of the supplementary pressure

F. The pressure of the large and small pump pressure gauges shows normal

G. Disassemble the pressure compensation cylinder and find that the oil seal is broken and worn

5. Conclusion:

By plugging the PT oil pipe of the pressure charging oil circuit board with a joint plug, the pressure can rise, and it can be concluded that the oil seal of the pressure charging cylinder is broken and worn, and it will return to normal after replacement.

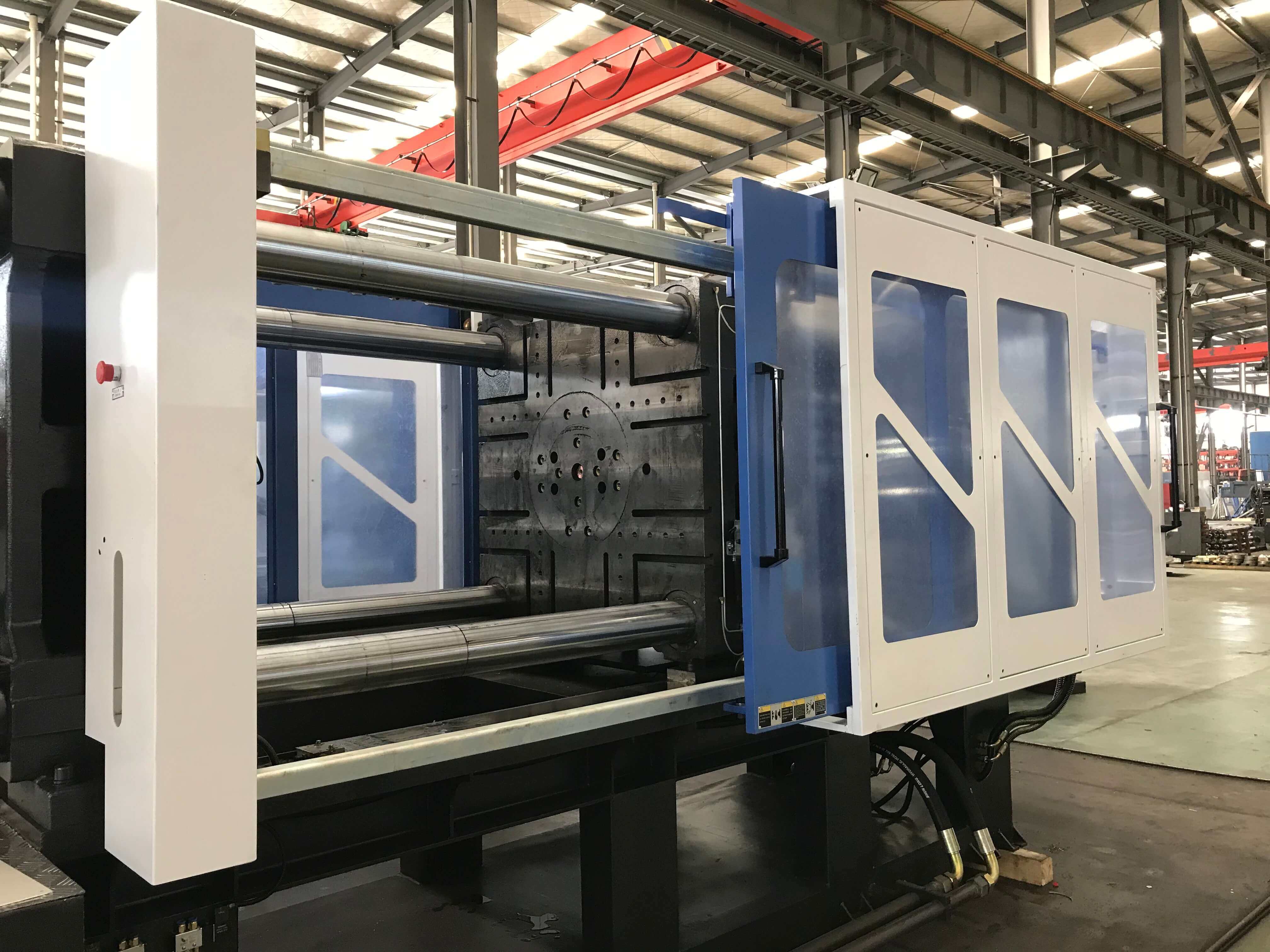

Main Features:

One.The Lock Section

1.Arch template, effectively protects the mould, especially suitable for big template with small mold.

2.The electric ruler is installed on the crosshead, the position is more precise.

3.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly

4.The connected tail-board stills itself with big lock shaft, improves tail-board strength, and ensures zero abrasion of the tail-board, easy for maintenance.

5.Connected movable plate, improves its rigidity and reduces deformation

6.Connected thrust bearing, improves its strength and stills itself with small lock shaft, ensures zero abrasion.

7.Arch template fully complies with mechanical property, largely improves template strength.

8.More reasonable toggle design, speeds and stabilizes mold opening and closing.

9.Adjustable movable plate mounting plate, makes the installation easier.

10.Mixed design of T-shape groove and die hole, increases universality of the mold.

Two.The Injection Section.

1.Bridge type support, improves injection smoothness.

2.Longer length-diameter ratio screw design, improves plasticizing effect.

3.Double seal structure, ensures no oil leakage.

4.Withhold type press plate, easy for debugging and assembly.

5.Bijection structure, improves stability.